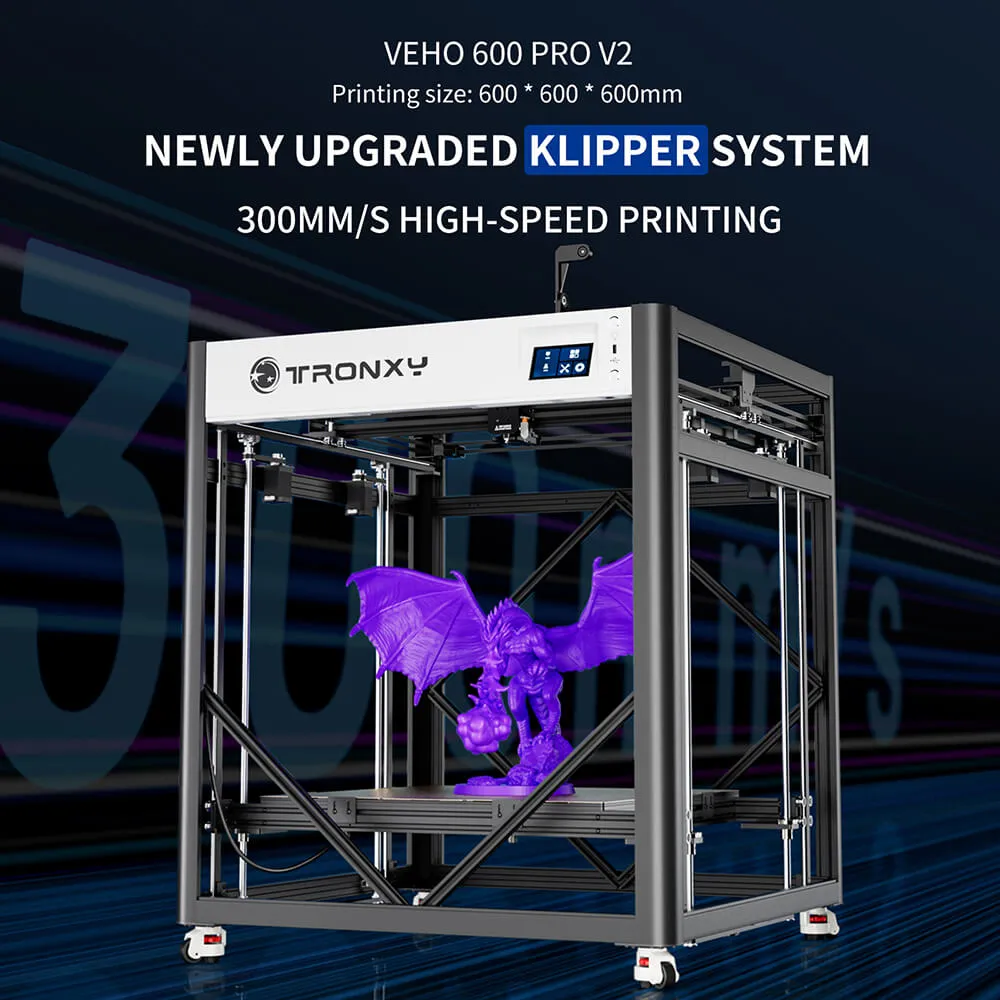

Innovative Klipper Upgrade

Experience unparalleled 3D printing with the newly upgraded Klipper firmware on the Tronxy Veho 600 Pro V2. This advanced system optimizes motion control, allowing for quicker and more precise printing, which means lower wait times and better outputs. Dive into the future of 3D technology with this powerful upgrade!

High-Speed Printing at 300mm/s

Unlock your creative potential with lightning-fast printing speeds of up to 300mm/s. The Tronxy Veho 600 Pro V2 is engineered for high performance, delivering intricate designs in record time. Ideal for professionals and hobbyists alike, it helps you achieve outstanding results without sacrificing quality.

Large Build Size

The impressive build size of 600x600x600mm opens up a world of possibilities for your projects. Create larger models, intricate prototypes, or multi-part assemblies without limitations. This expansive format gives you the freedom to unleash your imagination and realize your most ambitious designs.

Robust CoreXY Structure

Designed with a CoreXY structure, the Tronxy Veho 600 Pro V2 boasts superior stability and precision during printing. This innovative design minimizes vibrations and enhances speed, allowing for smooth operation and perfect detailing in each layer, making it a perfect companion for complex projects.

Built-in Safety Features

Ensure a hassle-free printing experience with built-in safety features, including a broken material detector. This innovative system pauses printing automatically when material is depleted or disconnected, allowing you to seamlessly continue once resolved—eliminating anxiety over print failures or interruptions.

Versatile Material Compatibility

The Tronxy Veho 600 Pro V2 accommodates a wide range of materials, including PLA, TPU, ABS, and more. This versatility lets users experiment with different filaments, enabling a vast array of applications from detailed models to functional parts. Let your creativity flourish with this adaptable 3D printer!

Newly Upgraded Klipper

High Speed 300mm/s Fast Printing

Veho 600 Pro V2 Assemble

Veho 600 Pro V2 Enclosure Assemble

Veho 600 Pro V2 Enclosure

Enclosure Material: Sheet Metal ShellTronxy Veho 600 Pro V2 3D Printer Klipper CoreXY High Speed Printing Large Format 3D Printer Fast 3D Printing Technology FDM Printing

Tronxy Veho 600 Pro V2

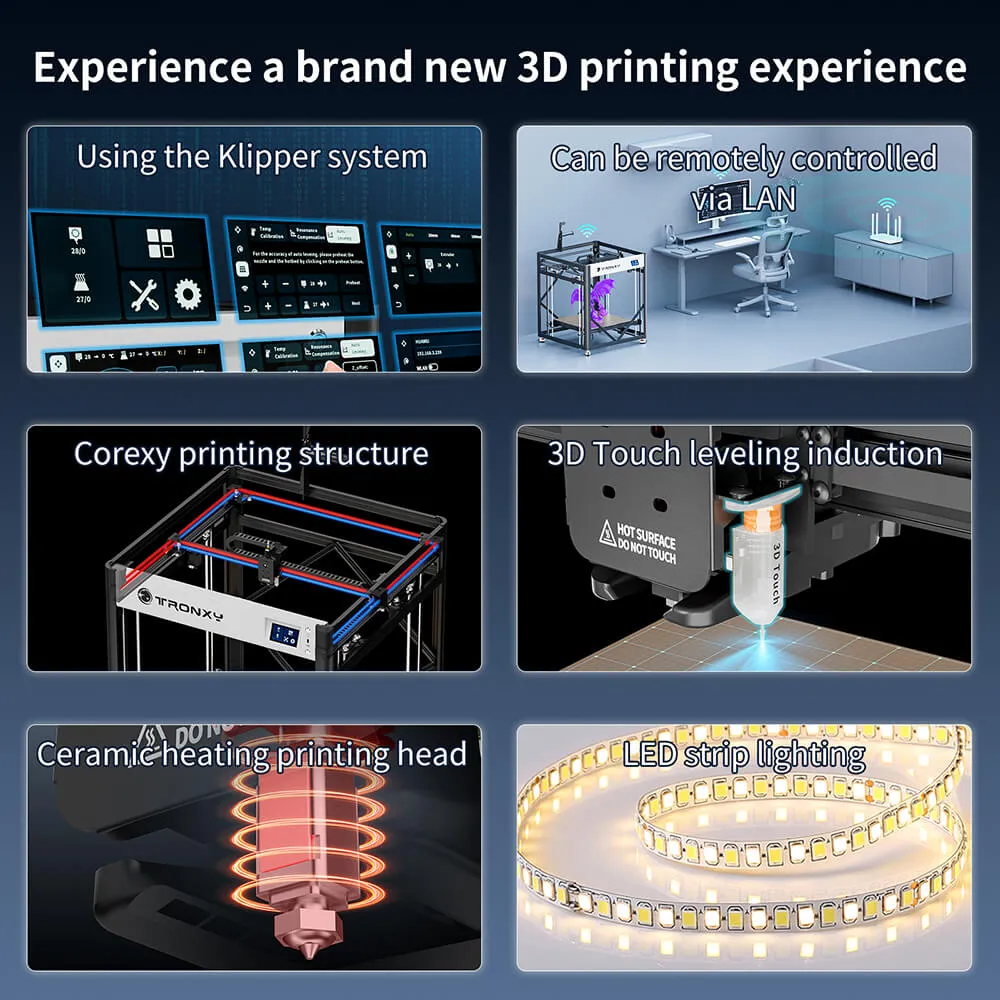

Using the Klipper system

Can be remotely controlled via LAN

Corexy printing structure

3D Touch leveling induction

Ceramic heating printing head

LED strip lighting

Klipper Firmware

Support remote control over local area networks, supports remote control of printing on both PC and mobile phones, enabling printing anytime, anywhere, offline printing can also be achieved through a USB flash drive in offline mode.

Corexy Printing Structure

The lightweight print head combined with Corexy structure is more conducive to high-speed operation, the maximum printing speed is 300mm/s and the acceleration is 10000/s.

The X-axis Adopts a Linear Guide Rail

Smooth and stable high-speed operation

Better Leveling Experience

Configure a 3D Touch leveling sensor with contact sensing for higher leveling accuracy.

Ceramic Heating Printing Head

The printing head is heated using ceramic sheets, which have a faster heating speed.

Lightweight Print Head

The extruder adopts an all metal mini extruder, which is lightweight and smooth for extrusion, lightweight design is more conducive to high-speed movement.

With Built-in Lighting

Equipped with LED lighting strips, providing all-round supplementary lighting, you can also clearly observe the printing details when printing in a dim environment.

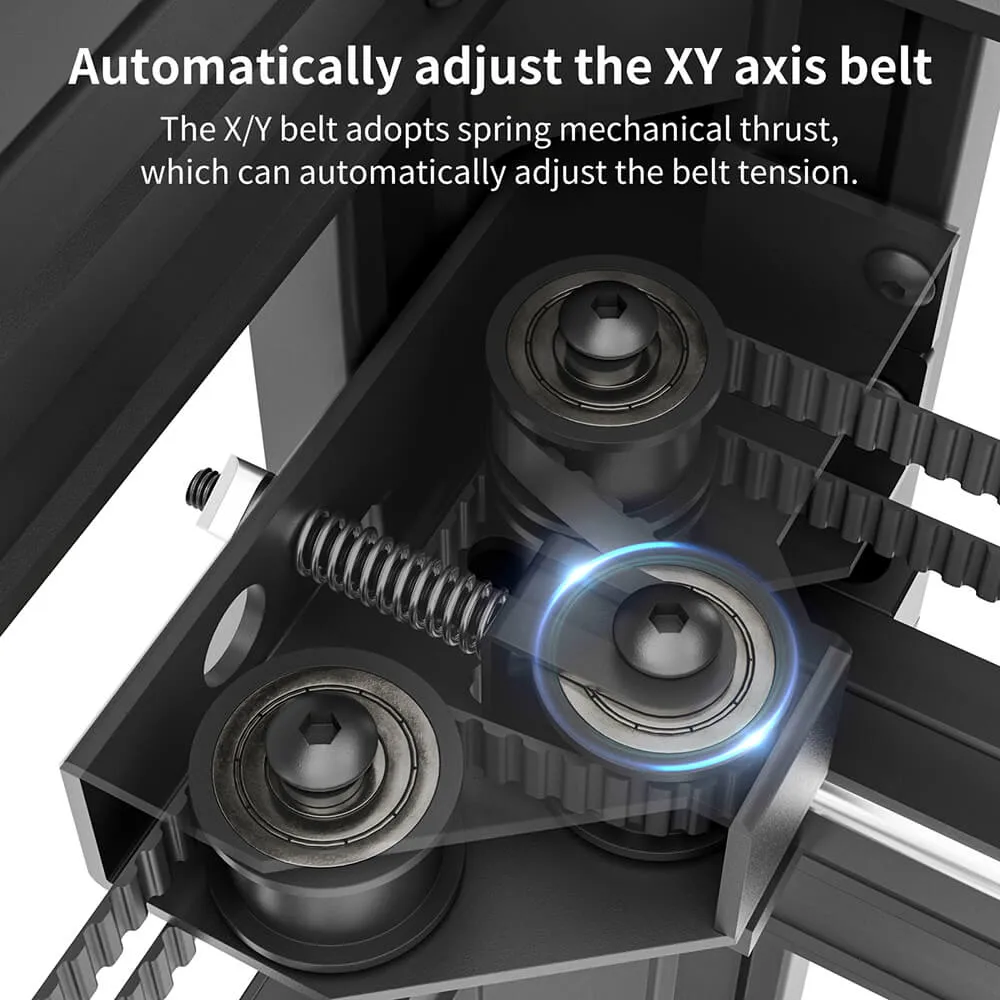

Automatically Adjust the XY Axis Belt

The X/Y belt adopts spring mechanical thrust, which can automatically adjust the belt tension.

Faster and More Uniform Preheating of the Hot Bed

The preheating of the hot bed adopts AC, with a short heating time and uniform heating of each part.

More Stable and Durable Metal Guide Rails

All guide rails are made of OSG external dual axis metal guide rails, the XYZ axis runs smoother and has a longer lifespan.

Configure Four Ball Screws

The ball screw transmission system is a point contact rolling motion, with low friction resistance, high sensitivity, no vibration during startup, and no crawling phenomenon at low speeds. Therefore, it can precisely control micro feed.

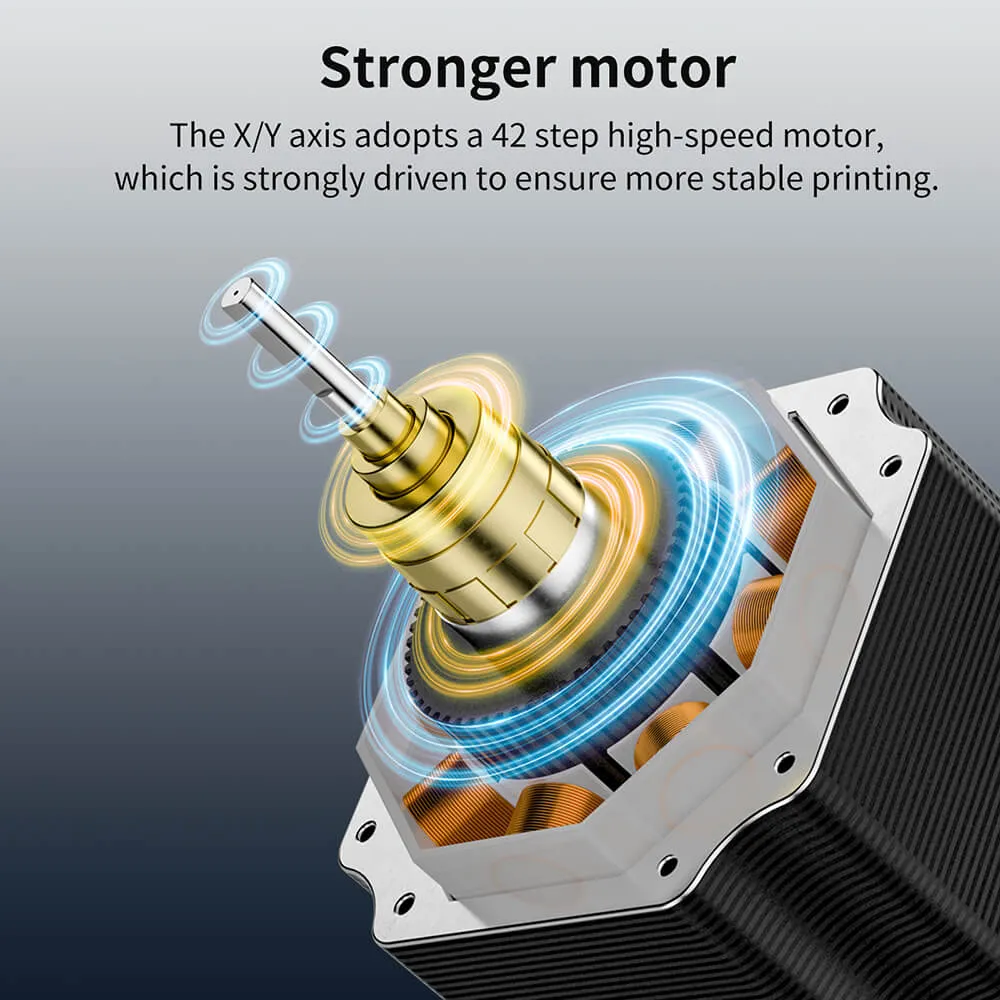

Stronger Motor

The X/Y axis adopts a 42 step high-speed motor, which is strongly driven to ensure more stable printing.

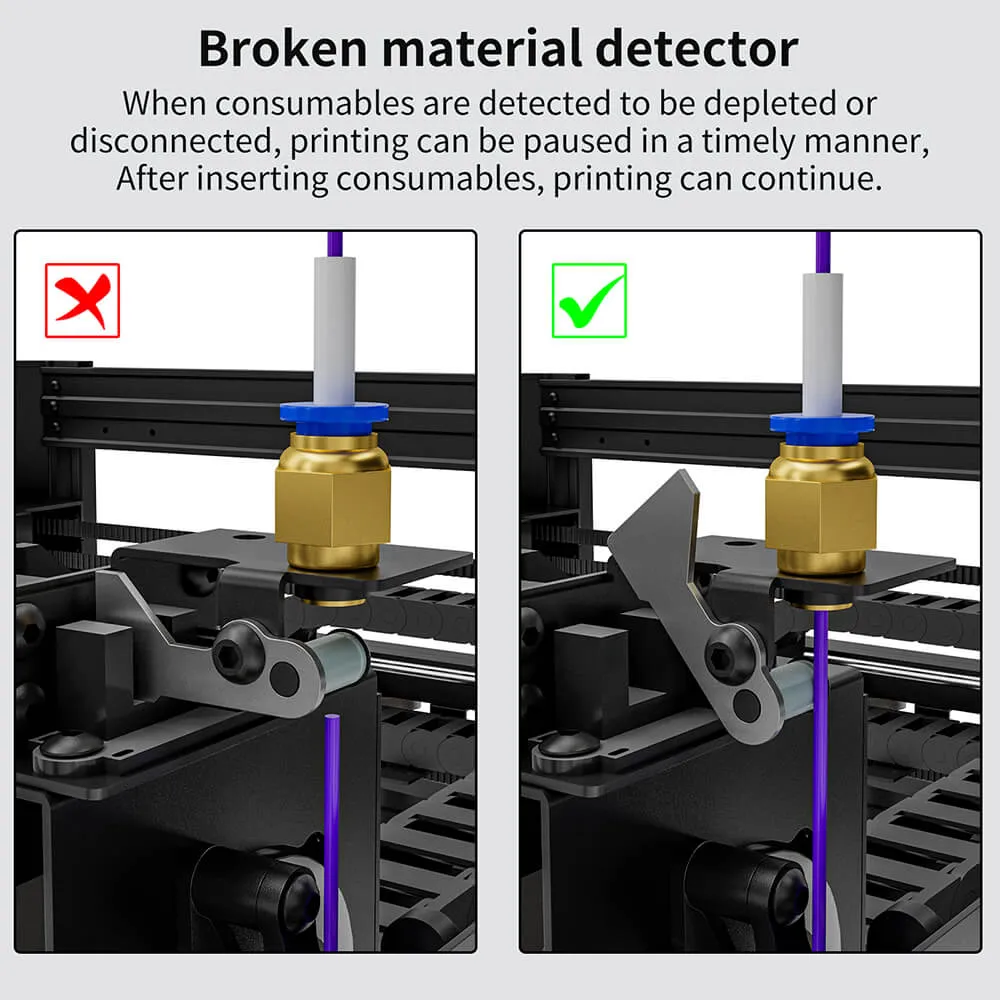

Broken Material Detector

When consumables are detected to be depleted or disconnected, printing can be paused in a timely manner, after inserting consumables, printing can continue.

Adjustable Pulley Foot Pad

Equipped with manually adjustable pulley foot pads for convenient movement of large format 3D printer.

●Raise the foot mat to easily move the machine. ●Lower the foot mat, the machine cannot be moved.

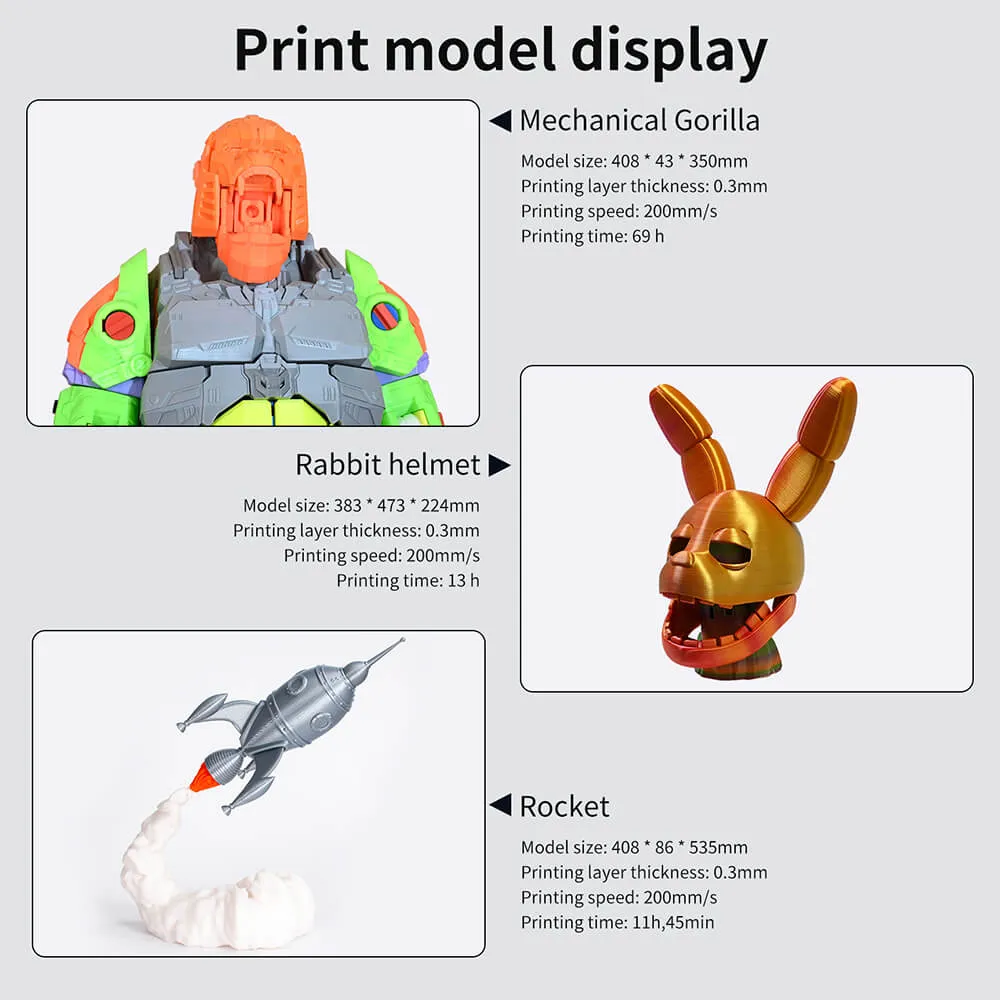

Mechanical Gorilla

Model Size: 408*43*350mm

Printing Layer Thickness: 0.3mm

Printing Speed: 200mm/s

Printing Time: 69 hours

Rabbit Helmet

Model Size: 383*473*224mm

Printing Layer Thickness: 0.3mm

Printing Speed: 200mm/s

Printing Time: 13 hours

Rocket

Model Size: 408*86*535mm

Printing Layer Thickness: 0.3mm

Printing Speed: 200mm/s

Printing Time: 11 hours 45 minutes

Specification:

Printing principle: FDMPrint Size: 600*600*600mm

Movement Speed: 300mm/s

Acceleration: 10000/s² (suggest 150mm/s²)

Print Accuracy: 0.1-0.4mm

Print Principle: FDM (Fused Deposition Molding)

Nozzle Size: Standard 0.6mm (1 free random size)

Nozzle Compatible with: 0.4/0.8/1.0/1.2/1.5/2.0mm

Position Accuracy: X/Y - 0.00625mm, Z - 0.00125mm

Input File Type: STL\OBJ\DAE\AMF\STEP

Slicing Software: Orca Slicer, Prusa, Cura

Connection Method: LAN connection, Ethernet cable, and USB

Power Supply: 24V/240W 50/60HZ

Filaments Support: PLA, TPU, ABS, Wood, PC, HIPS, Wooden filament etc.

Nozzle Temp 300℃ (MAX)

Machine Size: 850*851*1010mm

Machine weight: ≈ 45kg

Package A Weight ≈ 24.60KG

Package A Size: 785*672*205mm

Package B Weight ≈ 27.50KG

Package B Size: 995*302*370mm